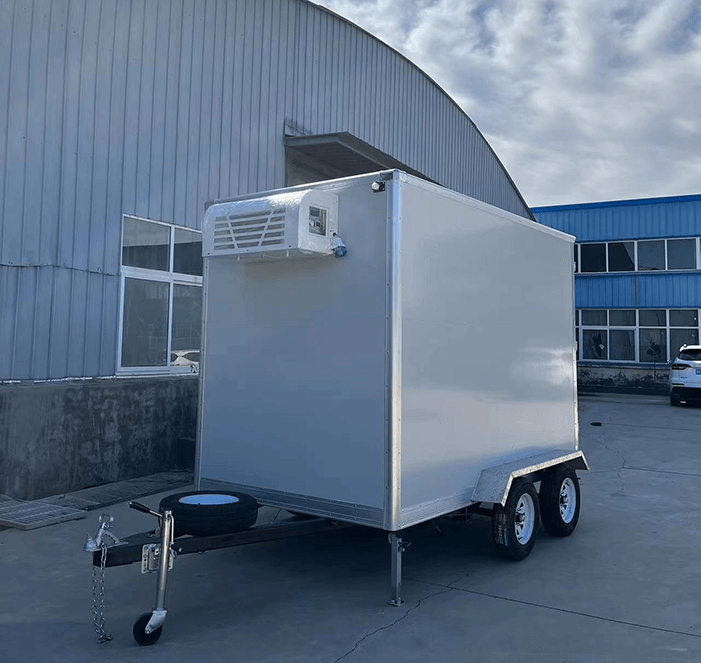

Portable Refrigerated Trailers: A Flexible Solution to Activate the "Last Mile" of the Cold Chain

In today's global cold chain logistics system, which continuously strives for efficiency and deeper coverage, a more flexible and adaptable mobile refrigeration equipment is becoming the focus of market attention – the portable refrigerated trailer. Compared to standardized large container refrigeration units, these small and medium-sized refrigerated units, which can be flexibly towed by standard trucks or tractor units, are quietly extending the cold chain network to the "capillary" level with their unparalleled mobility and adaptability to various scenarios, reaching logistics endpoints that traditional fixed facilities and large equipment cannot easily access.

Technical Positioning: Modular and Agile Temperature Assurance Units

The portable refrigerated trailer, in its technical essence, represents a design philosophy of "moderate integration and ultimate flexibility." It is not simply a scaled-down version of a large container unit, but rather an optimized and restructured design specifically for short-to-medium distance transportation, multi-point distribution, and scenarios with limited space.

Its core features lie first in its "size and load capacity adaptability." Available in various sizes, ranging from a few cubic meters to over ten cubic meters, it can be matched with ordinary freight vehicles of different tonnages, without requiring special chassis or heavy-duty towing equipment. This significantly lowers the entry barrier for cold chain capabilities, allowing any transportation fleet with basic qualifications to quickly access the service, greatly promoting the popularization of cold chain services.

Secondly, it achieves "deep coupling of the refrigeration system and cargo space." The efficient independent refrigeration unit is usually integrated at the front or top of the trailer body, powered by DC or AC power. It can be powered by the vehicle while in transit, or connected to mains power or a small generator when stationary. Although the temperature control system has less absolute power than large units, within its designed volume, it can still achieve precise temperature zone control and stable environmental maintenance, meeting diverse needs ranging from frozen meat to refrigerated pharmaceuticals.

More importantly, it offers "ease of use." The standard trailer hitch design allows for "one tractor unit with multiple trailers" for drop-and-hook transportation, significantly improving the efficiency of the tractor unit and reducing energy consumption during loading and unloading. At the same time, its smaller size facilitates maneuvering on urban roads, operating in fields, or directly backing up to the back doors of small shops, truly solving the "accessibility" problem of last-mile delivery.

Scenario Revolution: Empowering Distributed and On-Demand Cold Chain Needs

The rise of portable refrigerated trailers precisely meets the growing fragmented and on-demand cold chain logistics needs in modern business, and has triggered operational model transformations in multiple scenarios.

In the "farm-to-market" primary agricultural product distribution chain, it plays the dual role of a mobile pre-cooling station and a first-stage transport vehicle. Farmers or cooperatives can directly pre-cool and load products at the harvesting site, maximizing freshness, and then transport them directly to local wholesale markets or processing centers, bypassing the high investment of building cold storage facilities at the production site, shortening supply chain links, and increasing the added value of agricultural products.

In urban distribution and retail, it is a key carrier for "last-mile" cold chain fulfillment. Whether it's replenishing regional pre-warehouses for fresh food e-commerce, delivering to chain supermarket stores, or distributing ingredients from central kitchens of catering companies, small refrigerated trailers can achieve precise, flexible, and on-time delivery at lower costs and higher frequencies, effectively supporting the "multi-variety, small-batch, and fast-turnover" new retail model.

In terms of emergency response and temporary needs, it demonstrates a unique "plug-and-play" advantage. For temporary festive supplies storage, catering support for large outdoor events, and local material supply during public health emergencies, it can be quickly mobilized and deployed, rapidly forming reliable point-based cold chain nodes, supplementing the lack of flexibility in fixed facility networks.

Industry Impact: Promoting the Flattening and Democratization of Logistics Network Structures

The popularization of portable refrigerated trailers is having a profound structural impact on the cold chain industry ecosystem, the core of which is promoting the flattening of network structures and the democratization of service access.

It weakens the absolute constraint of logistics scale on cold chain capabilities. Small and medium-sized businesses, family farms, and even individual operators are no longer excluded from quality supply chains because their cargo volume is insufficient to fill a standard container or they cannot afford the rent of large cold storage facilities. By leasing or sharing individual trailer services, they can also obtain professional temperature-controlled transportation guarantees, allowing high-quality cold chain services to penetrate further and benefit a wider range of market participants.

This promotes the formation of regional and localized cold chain cycles. Numerous small, flexible trailer units can operate efficiently within local areas, connecting local producers, processors, and consumer markets, building a more resilient and shorter-chain localized cold chain system. This not only reduces carbon emissions from long-distance transportation but also enhances the stability of the local economy in the face of external supply chain fluctuations.

From an asset operation perspective, it has spawned a more lightweight and shared business model. Compared to large, capital-intensive equipment, trailers have a lower investment threshold and are easier to maintain, making them ideal for large-scale operation by third-party logistics companies, which can offer flexible service solutions such as time-based leasing and pay-per-use. This further optimizes the overall allocation efficiency of social cold chain resources.

Future Trends: Intelligent Integration and Energy Diversification

Looking ahead, the development of portable refrigerated trailers will be closely integrated with technological innovation and sustainable development goals.

Deep intelligence is a clear direction. Future trailers will integrate a wider range of sensors, not only monitoring internal temperature but also sensing cargo status (such as ethylene concentration). Through the Internet of Things and cloud management platforms, comprehensive upgrades in intelligent fleet scheduling, route optimization, energy consumption management, and preventive maintenance will be achieved, allowing small, dispersed assets to be included in a unified intelligent operation network.

Diversification and greening of energy supply are key issues. In addition to improving the energy efficiency ratio of the equipment itself, exploring the integration of small energy storage batteries, solar-assisted power supply systems, and efficient collaboration with new energy electric tractors will be important ways to reduce the carbon footprint of the entire transportation process. Especially in urban green delivery demonstration zones, the combination of electric refrigerated trailers and electric trucks will become standard configuration.

In addition, the standardization of interfaces with automated loading and unloading equipment will also be a development trend. Through unified pallet locks, door interfaces, and communication protocols, they can seamlessly connect with automated sorting lines, unmanned forklifts, and other equipment, improving turnover efficiency in modern logistics hubs.

Conclusion

Portable refrigerated trailers, with their unique flexibility and cost-effectiveness, are becoming an indispensable piece of the puzzle in perfecting a comprehensive cold chain coverage network. It doesn't pursue the maximization of individual equipment scale, but rather focuses on providing the most suitable and readily available temperature-controlled solutions in complex real-world logistics scenarios. Its widespread application signifies that cold chain logistics is moving beyond serving large-scale trade as a "main artery" and is further penetrating into the "capillaries" that activate regional economies and serve consumer needs. In the process of building an efficient, inclusive, and sustainable modern distribution system, these flexible and agile "small units" are playing an increasingly indispensable foundational role.