Silent Refrigeration: All-Electric Truck Refrigeration Units Lead a New Revolution in Cold Chain Transportation

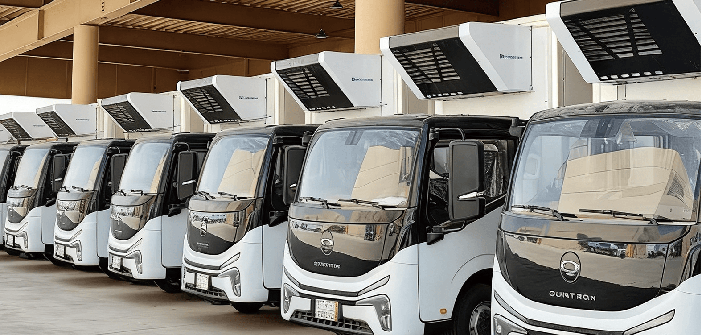

In the early morning city streets, a refrigerated truck silently drives through a residential area. The electric refrigeration unit inside precisely maintains the cargo temperature, all in almost complete silence.

The cold chain logistics industry is undergoing a "silent revolution." All-electric truck refrigeration units are replacing traditional diesel-driven systems at an astonishing pace. This transformation is not only about energy transition but will also reshape the operating model of the entire logistics industry.

Technological Leap

At the heart of this transformation is a new generation of refrigeration technology. All-electric refrigeration units utilize advanced electric compressors and variable frequency control systems, completely eliminating the reliance on diesel engines.

Compared to traditional refrigeration units, the energy conversion efficiency of electric systems is significantly improved, converting more energy directly into cooling capacity rather than dissipating it during the transmission process.

The integrated design of electric refrigeration units reduces the number of mechanical components, which not only lowers the failure rate but also simplifies maintenance procedures.

These systems employ a new thermal management solution, optimizing air circulation paths and heat exchange efficiency to significantly reduce energy consumption while maintaining the same cooling capacity.

Intelligent temperature control technology allows electric refrigeration units to automatically adjust their operating mode based on cargo type, external environment, and transportation stage. This adaptive capability ensures precise temperature control while maximizing energy savings.

Industry Transformation

The widespread adoption of all-electric refrigeration units is changing the operating logic of the cold chain industry. The high noise levels of traditional diesel units previously limited the operating time and range of cold chain vehicles, especially in urban residential areas and during nighttime hours.

The low-noise characteristics of electric systems break these limitations, allowing cold chain distribution to be more flexibly integrated into urban logistics systems.

The combination of electric refrigeration units and new energy trucks creates a completely zero-emission cold chain solution. This integration not only reduces exhaust emissions but also simplifies the vehicle energy management system, enabling cold chain transportation to meet increasingly stringent environmental regulations.

The maintenance requirements of electric refrigeration systems are significantly reduced. Traditional diesel units require regular oil changes, filter replacements, and exhaust system maintenance, while electric systems greatly reduce this type of mechanical maintenance, shifting the focus to the health of the electrical system. This shift in maintenance models is prompting corresponding technological upgrades and service adjustments in repair networks.

Environmental Benefits

The environmental benefits of electric refrigeration technology are multifaceted. First, there is a direct reduction in emissions – eliminating particulate matter, nitrogen oxides, and other pollutants from diesel combustion.

This is particularly important for cold chain vehicles operating in densely populated urban areas, contributing to improved urban air quality.

Increased energy efficiency means reduced overall energy consumption. Even if the electricity comes from non-renewable sources, the efficient operation of electric refrigeration units still reduces primary energy demand.

And as the proportion of renewable energy in the power grid increases, the carbon footprint of cold chain transportation will be further reduced.

The new refrigerants used in all-electric refrigeration units have a lower global warming potential, meaning that even in the event of a leak, the impact on the climate is far less than with traditional refrigerants. This dual environmental advantage – reduced direct emissions and reduced refrigerant impact – makes electric refrigeration units a truly green technology.

Real-World Challenges

Despite the promising outlook, all-electric refrigeration units still face real-world challenges in their widespread adoption. Driving range is one of the most pressing issues.

The operation of electric refrigeration systems relies entirely on on-board batteries, and the refrigeration process itself consumes a significant amount of energy, placing a dual burden on the vehicle's battery capacity and energy management.

The lack of charging infrastructure limits the operating range of electric refrigeration vehicles. Cold chain logistics often require long-distance transportation, and the lack of sufficient charging facilities along the route, especially high-power fast-charging stations, is a key factor hindering the widespread application of electric refrigeration units.

Initial purchase costs remain high. Although long-term operating costs may be lower, the higher initial investment is still a hurdle for many small and medium-sized logistics companies. Cost reduction depends on technological advancements and economies of scale.

Future Outlook

Looking ahead, technological innovation will continue to drive the development of electric refrigeration units. More efficient compressors, smarter thermal management systems, and more compact battery technology will further improve system performance.

Integrated design will allow refrigeration systems to be better integrated into the overall vehicle energy management system, enabling more optimized energy allocation.

The combination with renewable energy will open up new avenues for electric refrigeration. Innovative solutions such as vehicle-mounted solar auxiliary systems and hydrogen fuel cell range extension technology are under development. These technologies are expected to solve range anxiety issues and promote the expansion of electric refrigeration to a wider range of transportation scenarios.

The integration of intelligence and IoT technologies will redefine cold chain management. Future electric refrigeration units will not only be temperature control devices but also data collection and analysis platforms, capable of real-time monitoring of cargo status, predicting maintenance needs, and optimizing transportation routes.