From "Refrigerated Boxes" to "Mobile Intelligent Cold Storage": A Cold Chain Revolution on the Road

On the long roads connecting fields to tables, and factories to hospitals, fleets of heavy-duty trucks are undertaking one of modern society's most sophisticated missions – temperature-controlled transportation. Their cargo compartments may be filled with life-saving vaccines, fine wines at their peak flavor, or fresh food destined for supermarket shelves within the hour. Maintaining all of this is no longer a simple refrigeration machine, but the core of an intelligent mobile cold storage system – a new generation of trailer refrigeration units – integrating sensing, decision-making, and execution. This transformation from a "refrigerator" to an "environmental manager" is quietly driving a profound transformation of the entire cold chain logistics system towards greater reliability, efficiency, and intelligence.

Reshaping the Technological Core: From Mechanical Execution to Precise Control

Traditional trailer refrigeration equipment had the core task of simply resisting external high temperatures and maintaining low temperatures inside the compartment. Modern units, however, aim to create and maintain a highly stable, uniform, and energy-efficient microclimate under complex and variable external environments and internal heat loads. This goal is achieved through a fundamental upgrade of the technological core.

The new generation of units generally employs more efficient scroll or variable-frequency compressor technology, which, like the continuously variable transmission in a car, allows for "stepless adjustment" of cooling capacity, rather than simple "on/off" operation. This not only significantly reduces energy consumption but also keeps temperature fluctuations within the compartment to a minimum, which is crucial for the transportation of high-end biological preparations or premium food products. At the same time, advanced aerodynamic design is applied to the evaporator and condenser, ensuring uniform and gentle circulation of cold air within the cargo compartment, preventing localized overcooling that could damage goods or high temperatures in corners that could create hazards. These technological advancements transform the refrigeration unit from a "powerful cold source" into a temperature artist capable of "precise control."

The Soul of Intelligence: Data-Driven and Predictive Protection

The true revolution stems from the "soul" bestowed by intelligence. Modern high-end trailer refrigeration units are essentially intelligent terminals operating within the Internet of Things. A network of sensors distributed throughout the refrigeration units and cargo compartments forms its "neural network," continuously collecting dozens of data points, including temperature, humidity, door opening frequency, fuel efficiency, and component operating status.

This data is transmitted in real time to a cloud platform via a wireless network, providing transportation managers and cargo owners with a transparent "god's-eye view." They can intuitively monitor on a map interface whether the internal environment of each vehicle in transit meets the required standards, and any abnormal fluctuations will trigger multi-level warnings. More importantly, based on big data and algorithmic models, the system can perform predictive analysis. For example, by comparing historical data with current compressor load changes, the intelligent platform can predict potential failure risks dozens of hours in advance and recommend the optimal maintenance timing and plan, eliminating risks before they occur and ensuring the absolute reliability of high-risk transportation tasks such as long-distance cross-border transport. This leap from "passive repair" to "proactive health management" significantly enhances the resilience and efficiency of fleet operations.

Scenario-Based Innovation: Flexible Adaptation to Diverse Ecosystems

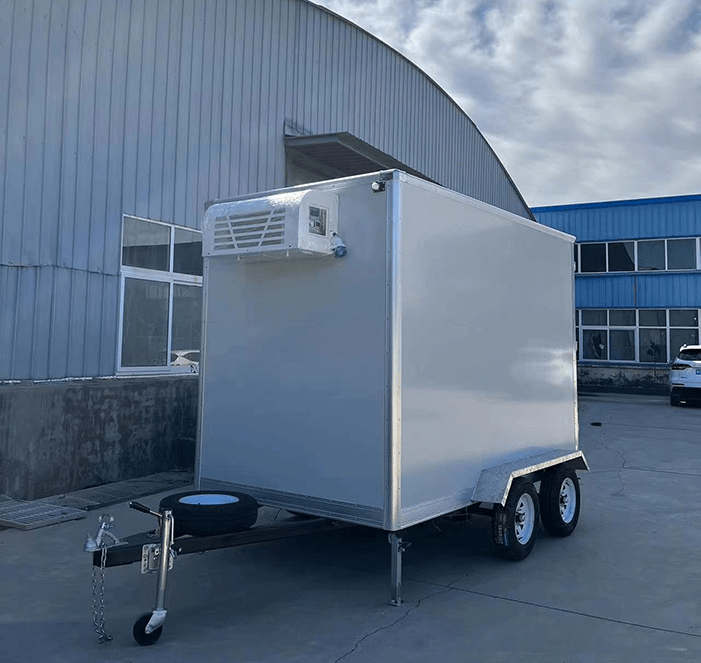

The diversification of cold chain transportation needs has driven scenario-based and modular innovation in refrigeration unit design. For "last-mile" scenarios such as urban joint distribution and community group buying, lightweight, low-noise, and electric small-scale units are rapidly developing. They can be flexibly adapted to medium-sized trucks, meeting environmental protection and regulatory requirements for navigating city streets.

On the other hand, to meet the increasingly complex multi-category co-distribution needs of fresh food e-commerce and chain restaurants, refrigeration units supporting independent control of multiple temperature zones have become mainstream. They can divide a single cargo compartment into multiple independently and precisely temperature-controlled spaces for freezing, refrigeration, ambient temperature, and even heating, enabling the simultaneous delivery of ice cream and chocolate, frozen steaks and fresh fruits in the same vehicle, greatly optimizing logistics costs and efficiency. This flexible adaptability allows mobile refrigeration technology to be deeply integrated into every aspect of the supply chain, from production warehouses to forward distribution centers, and from central kitchens to retail stores.

Green and Integrated: Driving Towards the Future

Facing the urgent global agenda of sustainable development, the "green evolution" of trailer refrigeration units is imperative. Industry exploration focuses on two key paths: first, applying environmentally friendly natural refrigerants that align with global trends, significantly reducing the carbon footprint and potential environmental risks of the equipment; and second, developing fully electric refrigeration systems deeply integrated with electric trucks. These systems utilize the vehicle's power battery for power, achieving "zero-emission" refrigeration during transportation and intelligently collaborating with the vehicle's energy management system to optimize overall energy consumption.

Looking ahead, as autonomous driving technology is gradually implemented in long-haul logistics, refrigeration units will become a highly collaborative and intelligent subsystem of the autonomous driving system. It will be able to plan the optimal energy consumption strategy in advance based on navigation-predicted routes, weather, and terrain information; and even automatically complete temperature control handover with intelligent warehouses in unattended loading and unloading scenarios. At that time, this "cool heart" on the road will evolve into a completely autonomous and highly reliable guardian of quality.

From the basic function of ensuring goods do not spoil to becoming an intelligent core that safeguards value and safety, the evolution of mobile trailer refrigeration units reflects the relentless pursuit of quality, efficiency, and certainty in modern logistics. It is no longer just a link in the cold chain, but a key force driving the upgrade of the entire system. When these smarter, quieter, and greener units speed down the road, they are protecting not only the temperature of the goods, but also the pulse of modern economic circulation and the promise of a high-quality life for people.