Electric Refrigeration Units Rise to Cold Chain Logistics, Ushering in a "Silent Refrigerated Era" for New Energy Trucks

With the continuous upgrading of urban distribution networks and increasingly stringent environmental requirements, a quiet technological revolution is taking place in the cold chain logistics sector. The traditional truck refrigeration methods, which relied on vehicle engines and generated loud noise, are gradually being replaced by independent, quiet, and efficient electric refrigeration units.

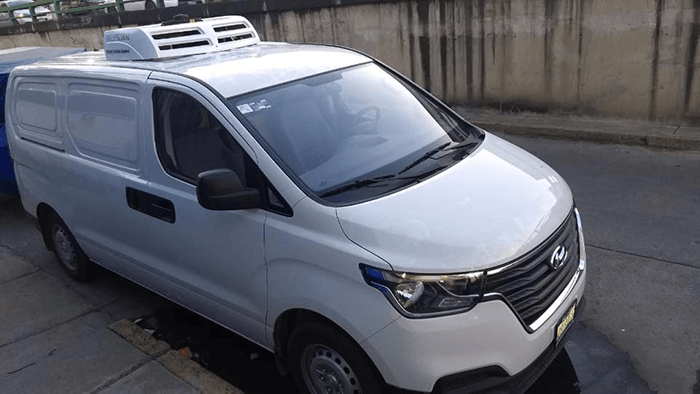

This refrigeration system, specifically designed for new energy light trucks, is reshaping the face of urban cold chain distribution with its unique advantages, driving the entire industry towards a greener, smarter, and more efficient direction.

Technological Transformation: From Mechanical Drive to Independent Electric Drive

Traditional truck refrigeration units are usually linked to the vehicle's engine. This mechanical drive mode has significant limitations. It not only increases the load and fuel consumption of the main engine but also cannot continue to operate after the vehicle is turned off, and it generates considerable noise during operation.

The emergence of electric refrigeration units has completely changed this model. It uses an independent electric system for drive, directly connected to the vehicle's battery pack. This design offers multiple advantages: it eliminates reliance on the truck's main engine, reducing mechanical losses; it enables precise variable frequency control, adjusting refrigeration power according to actual needs; and it significantly reduces operating noise, making it particularly suitable for operation in urban nighttime or residential areas.

Core technological advancements are reflected in several aspects: the application of high-efficiency variable frequency compressors significantly reduces energy consumption; the use of lightweight materials lightens the overall vehicle load; and the intelligent control system enables precise temperature regulation and remote monitoring. These technological innovations collectively drive a comprehensive improvement in the performance of electric refrigeration units.

Market-Driven: Dual Support from Environmental Policies and Industry Demand

The rapid development of electric refrigeration units benefits from the combined effect of multiple factors. Environmental policies are a key driving force. With the establishment of low-emission zones in many cities worldwide, environmental requirements for commercial vehicles are constantly increasing, giving new energy trucks more road rights advantages. As an important component of this, electric refrigeration units are naturally favored.

The changing demands of the cold chain logistics industry itself cannot be ignored. The booming development of fresh food e-commerce and the improvement of pharmaceutical cold chain standards have placed higher demands on temperature control during transportation. Electric refrigeration units, with their precise temperature control and stable operation, can better ensure the quality and safety of sensitive goods.

Furthermore, operating costs are also a crucial factor. Although the initial investment may be higher, the energy efficiency and ease of maintenance demonstrated by electric refrigeration units in long-term use bring considerable economic benefits to operators. These advantages are further amplified, especially in urban delivery scenarios.

Application Scenarios: Diverse Needs Drive Wide Adaptability

The application of electric refrigeration units is rapidly expanding to multiple cold chain logistics sectors, meeting diverse transportation needs.

In urban fresh food delivery, electric mini-trucks paired with high-efficiency refrigeration units can achieve green delivery for the "last mile." These vehicles navigate the streets and alleys, and due to their low-noise characteristics, they do not disturb residents even when operating at night or in the early morning, while simultaneously ensuring the freshness of perishable foods such as fruits, vegetables, and dairy products.

Pharmaceutical cold chain transportation has extremely stringent requirements for temperature stability and accuracy. Electric refrigeration units can provide a continuously stable refrigeration environment, ensuring the safety of temperature-sensitive pharmaceutical products such as vaccines and biological agents during transportation, which has become particularly important in recent years.

Furthermore, electric refrigeration units are demonstrating broad adaptability in emerging scenarios such as community group buying, chain restaurant delivery, and high-end flower transportation. Their flexible installation capabilities allow them to adapt to different truck sizes and meet various customized needs.

Competitive Landscape: Traditional Giants and Emerging Forces Compete in the Same arena

The electric refrigeration unit market has attracted numerous companies, resulting in a diversified competitive landscape. Traditional refrigeration equipment manufacturers, leveraging their technological accumulation and brand advantages, have taken the lead in launching electric product series, attempting to maintain their leading position in the new energy transformation.

Meanwhile, some companies specializing in new energy technologies have also joined the competition, often possessing unique innovations in power control systems and energy efficiency optimization. The emergence of these emerging forces has brought more diversified solutions to the market and accelerated technological progress across the industry.

Different manufacturers' products emphasize different aspects such as cooling efficiency, energy consumption control, and intelligent functions, meeting the needs of different customer groups. This competitive landscape prompts companies to continuously invest in research and development, driving rapid iteration and cost optimization of electric refrigeration unit technology.

Future Outlook: Intelligentization and Integration as Development Directions

Looking ahead, the development of electric refrigeration units will exhibit several distinct trends. Improving the level of intelligence will be a key direction. Through IoT technology, refrigeration units can achieve functions such as remote monitoring, fault warning, and energy efficiency analysis, integrating into a wider range of cold chain management systems and improving the transparency and management efficiency of the entire supply chain.

Deep integration with new energy trucks is another development trend. Future electric refrigeration units will no longer be standalone additions, but rather highly integrated components with the vehicle's electrical and thermal management systems, achieving optimal energy allocation and utilization.

Furthermore, with the maturity of technology and increased production, the cost of electric refrigeration units is expected to further decrease, enabling their application not only in high-end cold chain transportation but also in broader general cold chain needs, driving the green upgrade of the entire industry.

With the acceleration of urbanization and consumers' increasing demands for the quality of fresh produce, the importance of cold chain logistics is becoming increasingly prominent. Electric mini-truck refrigeration units, as a key technology in this system, are supporting the green transformation of urban cold chain distribution networks with their quiet, efficient, and environmentally friendly characteristics, subtly improving our quality of life.