Driving into the Green Lane: Electric Refrigerated Trucks Reshape the Cold Chain Transportation Ecosystem

The early mornings in cold chain logistics are always exceptionally busy. In the logistics parks on the outskirts of the city, rows of refrigerated trucks quietly await their tasks for the day. Unlike before, the roar of engines is becoming increasingly rare, replaced by the almost silent hum of electric motors. This change is quietly rewriting the entire landscape of the cold chain transportation industry.

Technological Breakthroughs: The Key Evolution of Electric Refrigerated Trucks

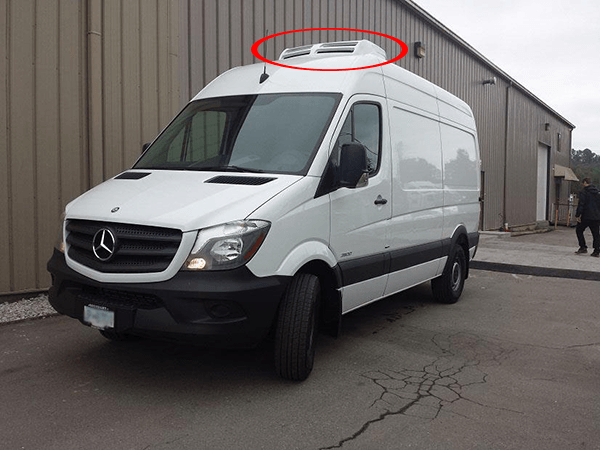

Electric refrigerated trucks are not simply a matter of replacing traditional fuel-powered vehicles with electric power systems. The core of this transformation lies in solving the unique "dual energy consumption" problem of refrigerated trucks – the need to both power the vehicle and provide stable electricity to the refrigeration unit.

Early electric refrigerated trucks often faced the dilemma of insufficient range. After loading goods and starting the refrigeration system, the actual driving range was often significantly reduced. However, this pain point has now been significantly alleviated. The new generation of electric refrigerated trucks achieves intelligent power distribution between driving and refrigeration by optimizing the vehicle's overall energy management system. The system can independently adjust the refrigeration power based on cargo temperature requirements, environmental conditions, and remaining mileage, maximizing range while ensuring cargo quality.

Refrigeration technology itself is also undergoing an electrification transformation. Traditional fuel-powered refrigerated trucks often rely on the engine to directly drive the compressor, while electric refrigerated trucks use independent electric compressors. This design not only reduces energy conversion losses but also makes temperature control more precise. The electric compressor can achieve stepless speed regulation, adjusting the cooling capacity in real time according to temperature changes in the cargo compartment, controlling temperature fluctuations within a very narrow range.

Intellignt Empowerment: Redefining Cold Chain Management

The combination of electrification and intelligence is redefining the management model of cold chain transportation. In traditional cold chain transportation, temperature monitoring often relies on manual recording or simple data loggers, leading to delays and incomplete information. The new generation of electric refrigerated trucks integrates data such as temperature monitoring, location tracking, and operating status into a unified platform, achieving full-process visual management.

Through the intelligent temperature control system, managers can remotely start the pre-cooling program before loading goods to ensure the cargo compartment reaches the appropriate temperature. During transportation, the system not only continuously monitors the temperature at various points in the cargo compartment but also automatically adjusts the refrigeration parameters based on changes in the external environment. When the temperature is abnormal, the system immediately sends an alert to the driver and managers so that remedial measures can be taken promptly.

The accumulation and analysis of this data also provides a basis for companies to optimize transportation routes, improve loading schemes, and increase energy efficiency. Through deep learning of historical transportation data, the system can predict energy consumption under different seasons and routes, providing intelligent suggestions for vehicle scheduling and charging plans.

Market Drivers: Multiple Factors Drive Industry Transformation

The rapid popularization of electric refrigerated trucks is due to the combined impetus of policy guidance, market demand, and technological advancements. Under environmental protection and carbon emission reduction targets, many regions have imposed restrictions on the driving areas and times of fuel-powered commercial vehicles, while new energy vehicles often enjoy priority road rights. This policy direction directly influences the vehicle procurement decisions of logistics companies.

Operational cost advantages are also an important factor attracting companies to electric refrigerated trucks. Although the purchase cost of electric refrigerated trucks is usually higher than that of traditional fuel vehicles, their energy costs during the use phase are significantly lower. Especially in urban delivery scenarios, the frequent start-stop driving mode is more suitable for the energy recovery characteristics of electric vehicles, further expanding the energy consumption advantage.

The specialization and high-quality requirements of the cold chain logistics market itself have also created conditions for the application of electric refrigerated trucks. Sub-sectors such as pharmaceutical cold chain and high-end food transportation have strict standards for temperature control accuracy and traceability of the transportation process, which is precisely where intelligent electric refrigerated trucks excel.

Challenges and the Future: Multidimensional Thinking on Industry Development

The development of electric refrigerated trucks still faces a series of challenges. Insufficient charging infrastructure is a major bottleneck restricting their application in long-distance transportation. Cold chain transportation often has time-sensitive requirements, and charging time may disrupt tight transportation schedules. To address this, the industry is exploring battery swapping models, fast charging technologies, and range-extending solutions to meet the needs of different transportation scenarios.

Vehicle residual value assessment and battery recycling systems are also important factors affecting the promotion of electric refrigerated trucks. As the first batch of electric refrigerated trucks enters the replacement cycle, establishing fair used vehicle valuation standards and a complete battery recycling chain has become crucial for the sustainable development of the industry.

In the future, with the improvement of battery energy density and faster charging speeds, the application scope of electric refrigerated trucks will further expand. Alternative technologies such as hydrogen fuel cells are also being tested in the refrigerated truck field, and are expected to provide new solutions for long-distance, heavy-duty cold chain transportation. The deep integration of intelligent technologies will drive the transformation of electric refrigerated trucks from mere transportation tools to "mobile intelligent cold chain nodes." Through vehicle-to-everything (V2X) technology, refrigerated trucks can achieve data interoperability with warehousing systems, traffic management systems, and order platforms, forming a more efficient and collaborative cold chain logistics network.

From early morning urban deliveries to cross-regional trunk line transportation, electric refrigerated trucks are safeguarding every link of the cold chain logistics in a cleaner and smarter way. This is not only a revolution in power systems but also a significant milestone in the transformation of the entire cold chain industry towards efficiency, transparency, and sustainable development. In this silent revolution, the green future of cold chain logistics is slowly arriving.